Introduction: Unveiling the Process of Clove Oil Production

Clove oil, with its distinct aroma and versatile properties, has gained popularity in various industries, including aromatherapy, personal care, and culinary applications. But have you ever wondered how this precious oil is produced? In this article, we will take a closer look at the fascinating process of clove oil production, from the collection of buds to the extraction of the essential oil.

The Journey Begins: Collecting Clove Buds

The first step in clove oil production is the collection of clove buds. Clove trees (Syzygium aromaticum) reach maturity after approximately 7 years, and it is during this stage that the flower buds are harvested. Experienced harvesters carefully pluck the buds by hand, ensuring they are still tightly closed and have not yet bloomed.

Drying the Buds: Enhancing Aroma and Flavor

After harvesting, the clove buds are carefully dried to enhance their aromatic and flavorful qualities. Traditionally, the buds are spread out on mats or bamboo trays and exposed to the sun. The drying process usually takes several days and requires regular turning and monitoring to ensure even drying. The buds gradually change color from a vibrant green to a rich reddish-brown during the drying process.

Steam Distillation: Extracting Clove Oil

Once the buds are thoroughly dried, they are ready for the extraction of clove oil. Steam distillation is the most common method used to obtain clove oil. The dried buds are placed in a distillation apparatus, and steam is passed through them. The steam helps release the aromatic compounds present in the buds, which then evaporate and rise to the top of the apparatus.

As the steam cools down, it condenses into a liquid, forming a mixture of water and clove oil. The two components can be separated by gravity. The heavier clove oil, which contains the aromatic compounds, is collected from the bottom, while the lighter water component, known as the hydrosol or floral water, is collected from the top.

Refining the Oil: Removing Impurities

The collected clove oil undergoes a refining process to remove impurities and ensure its purity and quality. This refining process typically involves filtration and sometimes additional purification methods, such as fractional distillation or solvent extraction. These processes help eliminate any remaining water, plant matter, or undesirable compounds, resulting in a more concentrated and refined clove oil.

Quality Testing: Ensuring Purity and Potency

To ensure the quality and potency of clove oil, it undergoes rigorous testing. Various factors, such as the concentration of aromatic compounds, moisture content, and absence of contaminants, are evaluated to determine the oil's quality. These tests help guarantee that the clove oil meets the industry standards and is safe for its intended use.

Bottling and Packaging: Ready for the Market

Once the clove oil has been refined and tested, it is ready for bottling and packaging. The oil is carefully transferred into dark glass bottles to protect it from light and extend its shelf life. Labeling and proper packaging ensure that consumers receive accurate information about the oil's origin, quality, and usage instructions.

Frequently Asked Questions about Clove Oil Production

-

Q: Can clove oil be produced at home? A: While it is possible to extract clove oil at home using DIY methods, it is important to note that the process requires specialized equipment and expertise. For safety and quality reasons, it is generally recommended to purchase clove oil from reputable suppliers.

-

Q: How long does it take to produce clove oil from start to finish? A: The entire process of clove oil production, from harvesting to bottling, can take several weeks. Drying the buds alone can take several days, and the steam distillation process requires careful monitoring and time for condensation.

-

Q: Are there different grades of clove oil? A: Clove oil can be categorized into different grades based on factors such as the quality of the raw materials, the extraction method used, and the purity of the final product. Higher grades generally indicate higher quality and purity.

-

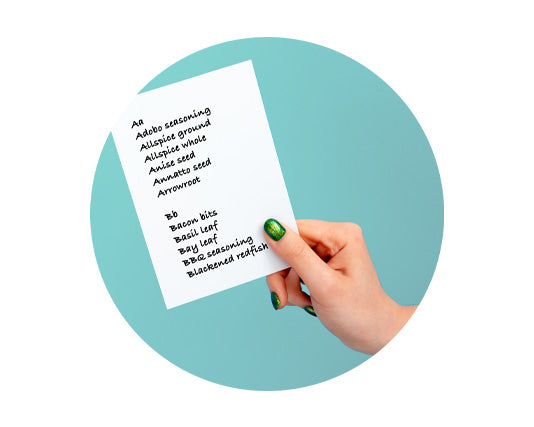

Q: What are the main components responsible for the aroma and therapeutic properties of clove oil? A: Eugenol is the primary component responsible for the distinct aroma and therapeutic properties of clove oil. Other important components include eugenyl acetate, beta-caryophyllene, and alpha-humulene.

-

Q: What are the common uses of clove oil? A: Clove oil has a wide range of uses, including as an ingredient in aromatherapy blends, dental care products, topical ointments, and flavorings in food and beverages. It is also valued for its potential antimicrobial, analgesic, and antioxidant properties.

-

Q: How should clove oil be stored to maintain its quality? A: Clove oil should be stored in a cool, dark place, away from direct sunlight and heat sources. Proper storage helps preserve its potency and extends its shelf life.

Conclusion: The Art and Science of Clove Oil Production

The production of clove oil is a meticulous process that combines traditional techniques with modern refining methods. From the careful collection of buds to the steam distillation and refining processes, each step is essential in creating the aromatic and potent clove oil we know and love. So, the next time you enjoy the soothing aroma or benefit from the therapeutic properties of clove oil, remember the intricate journey it undertakes to reach your hands.

Alert: While spices can have many beneficial properties for health, using them for medical purposes should be done under the guidance and supervision of a healthcare professional or specialist. Some spices may interact with medications or cause adverse reactions in certain individuals, and it is important to use them safely and appropriately. If you are considering using spices for a medical condition, it is important to consult with a healthcare professional before doing so.