Black pepper is made from the dried fruit, or peppercorns, of the Piper nigrum plant, which is native to India and Southeast Asia. The process of making black pepper involves several steps:

-

Harvesting: The fruit of the Piper nigrum plant is harvested when it is still green and not yet fully mature. This is done by hand or with machines, depending on the location and scale of the operation.

-

Blanching: The harvested peppercorns are then briefly soaked in hot water or exposed to steam to remove the outer layer of skin.

-

Drying: The blanched peppercorns are spread out in the sun to dry, or they may be dried in a machine. This step can take several days, during which time the peppercorns turn dark and shrivel up.

-

Hulling: Once the peppercorns are fully dry, the outer layer of skin is removed, leaving the hard, black seed inside.

-

Cleaning and sorting: The black pepper seeds are then cleaned and sorted by size and quality. Lower-quality seeds may be ground into a powder, while higher-quality seeds are sold whole.

-

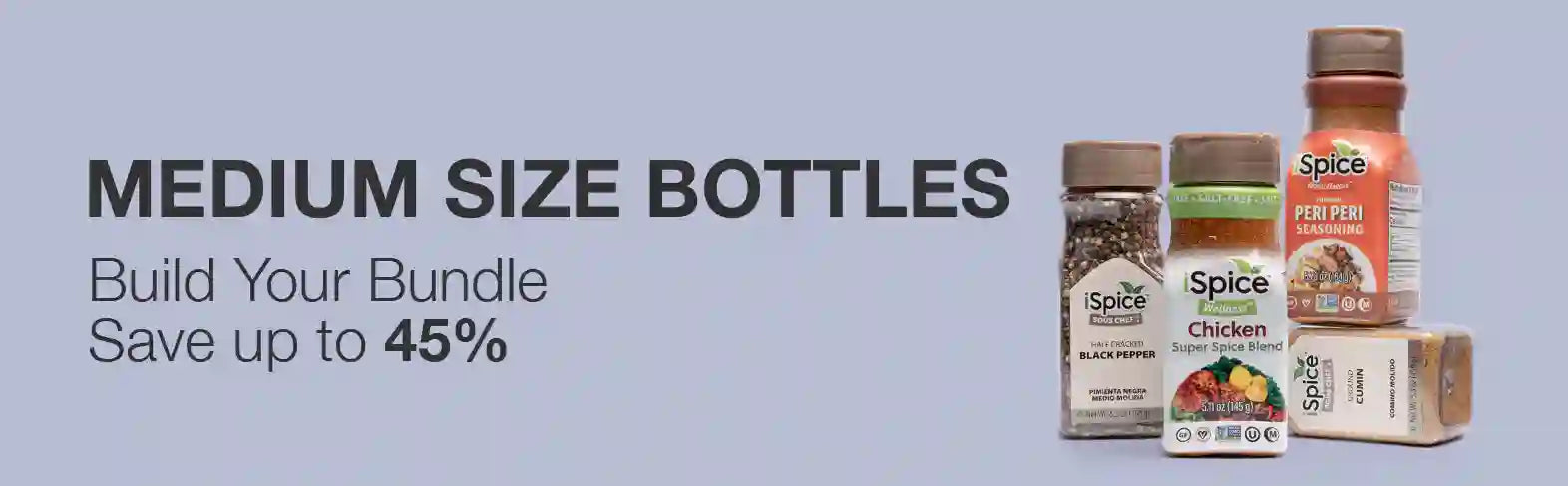

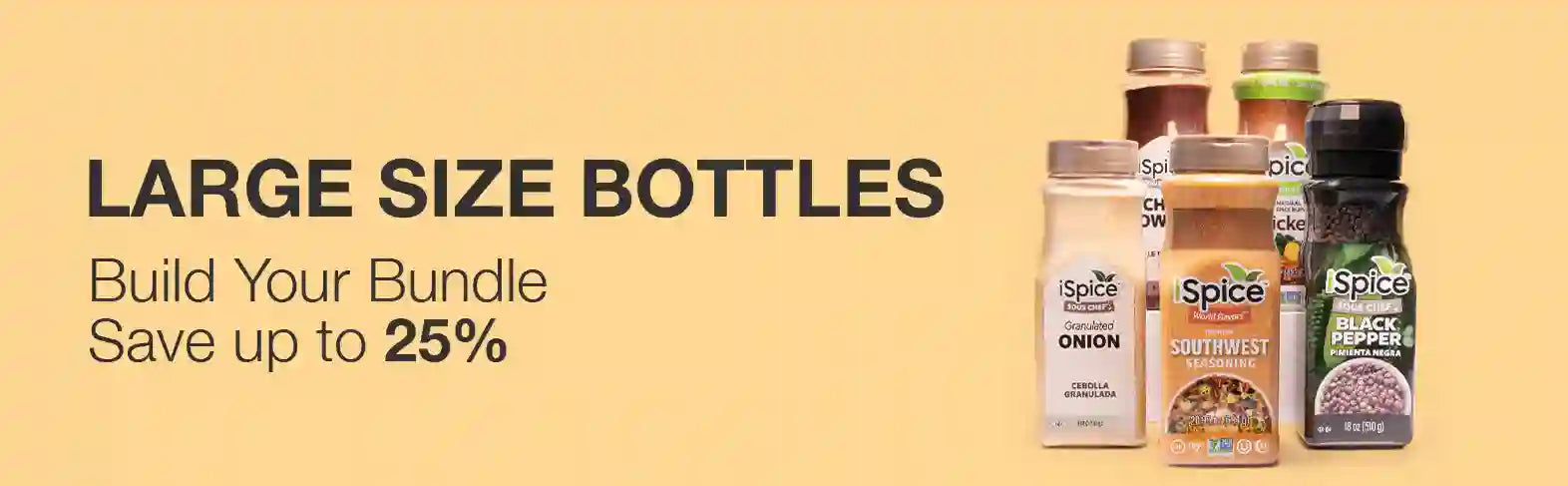

Packaging: The final step is to package the black pepper seeds or powder for distribution and sale.

Overall, the process of making black pepper involves careful harvesting, blanching, drying, hulling, cleaning, and sorting to produce a high-quality product that is enjoyed by people around the world.

Alert: While spices can have many beneficial properties for health, using them for medical purposes should be done under the guidance and supervision of a healthcare professional or specialist. Some spices may interact with medications or cause adverse reactions in certain individuals, and it is important to use them safely and appropriately. If you are considering using spices for a medical condition, it is important to consult with a healthcare professional before doing so.